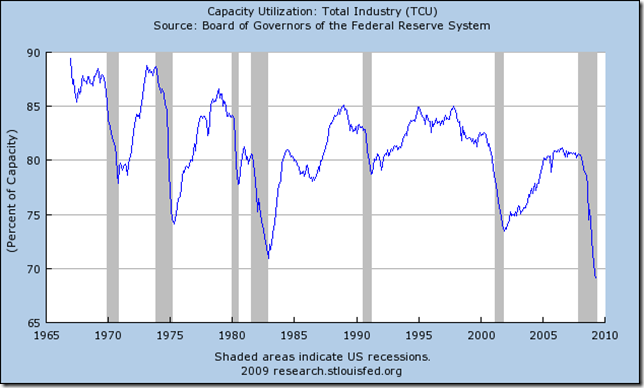

Industrial Production down again:

Capacity Utilization hits a record low since series began:

We hear so often that “American manufacturing is dead.” But the U.S. is still the world’s biggest manufacturer (reference), followed by Japan and China. To paraphrase leftist pro-labor economist Robert Reich, via Forbes (emphasis added in article), “manufacturing—up, manufacturing jobs—down,” continuing a long-term trend. (I learned this many years ago writing a paper about automation in seventh grade.)

What Reich does not address is the flagrantly clubby, classist increase in income inequality that has nothing to do with the requirements of the “new,” “symbolic analyst” jobs. What American CEO (except in tech) came up by that route? American CEOs pay themselves outrageous amounts because they can; their boards are all buddies, and the workers’ pension funds that own their companies don’t take an activist stance on this, being too busy collecting their management fees to rock the boat. Reich does mention that this is having generational follow-on effects as middle- and lower-middle class kids are having trouble getting a good education. I learned from a Bill Gates Ted.org talk that one-third of American students today do not finish high school! More than ever, the American people are our greatest national resource, and we’re letting that resource depreciate at a rapid rate.

Reich opposes letting the dollar fall to stimulate export demand. Who can buy anyway? But when the dollar does fall, it will benefit our manufacturing sector.

The global excess capacity at this historical moment must be massive. It’s time to realize “we have enough stuff.” And to provide a livable wage to those who need work.

Made In America

Manufacturing Jobs Are Never Coming Back

Robert B. Reich, 05.28.09, 06:00 PM EDTIncreasingly, machines make things, not people--and that should be great news for the U.S.

Robert Reich

It doesn't make sense for America to try to enlarge manufacturing as a portion of the economy. Even if the U.S. were to seal its borders and bar any manufactured goods from coming in from abroad--something I don't recommend--we'd still be losing manufacturing jobs. That's mainly because of technology.

When we think of manufacturing jobs, we tend to imagine old-time assembly lines populated by millions of blue-collar workers who had well-paying jobs with good benefits. But that picture no longer describes most manufacturing. I recently toured a U.S. factory containing two employees and 400 computerized robots. The two live people sat in front of computer screens and instructed the robots. In a few years this factory won't have a single employee on site, except for an occasional visiting technician who repairs and upgrades the robots.

Factory jobs are vanishing all over the world. Even China is losing them. The Chinese are doing more manufacturing than ever, but they're also becoming far more efficient at it. They've shuttered most of the old state-run factories. Their new factories are chock full of automated and computerized machines. As a result, they don't need as many manufacturing workers as before.

Economists at Alliance Capital Management took a look at employment trends in twenty large economies and found that between 1995 and 2002--before the asset bubble and subsequent bust--twenty-two million manufacturing jobs disappeared. The United States wasn't even the biggest loser. We lost about 11% of our manufacturing jobs in that period, but the Japanese lost 16% of theirs. Even developing nations lost factory jobs: Brazil suffered a 20% decline, and China had a 15% drop.

What happened to manufacturing? In two words, higher productivity. As productivity rises, employment falls because fewer people are needed. In this, manufacturing is following the same trend as agriculture. A century ago, almost 30% of adult Americans worked on a farm. Nowadays, fewer than 5% do. That doesn't mean the U.S. failed at agriculture. Quite the opposite. American agriculture is a huge success story. America can generate far larger crops than a century ago with far fewer people. New technologies, more efficient machines, new methods of fertilizing, better systems of crop rotation, and efficiencies of large scale have all made farming much more productive.

Manufacturing is analogous. In America and elsewhere around the world, it's a success. Since 1995, even as manufacturing employment has dropped around the world, global industrial output has risen more than 30%.

We should stop pining after the days when millions of Americans stood along assembly lines and continuously bolted, fit, soldered or clamped what went by. Those days are over. And stop blaming poor nations whose workers get very low wages. Of course their wages are low; these nations are poor. They can become more prosperous only by exporting to rich nations. When America blocks their exports by erecting tariffs and subsidizing our domestic industries, we prevent them from doing better. Helping poorer nations become more prosperous is not only in the interest of humanity but also wise because it lessens global instability.

Want to blame something? Blame new knowledge. Knowledge created the electronic gadgets and software that can now do almost any routine task. This goes well beyond the factory floor. America also used to have lots of elevator operators, telephone operators, bank tellers and service-station attendants. Remember? Most have been replaced by technology. Supermarket check-out clerks are being replaced by automatic scanners. The Internet has taken over the routine tasks of travel agents, real estate brokers, stock brokers and even accountants. With digitization and high-speed data networks a lot of back office work can now be done more cheaply abroad.

Any job that's even slightly routine is disappearing from the U.S. But this doesn't mean we are left with fewer jobs. It means only that we have fewer routine jobs, including traditional manufacturing. When the U.S. economy gets back on track, many routine jobs won't be returning--but new jobs will take their place. A quarter of all Americans now work in jobs that weren't listed in the Census Bureau's occupation codes in 1967. Technophobes, neo-Luddites and anti-globalists be warned: You're on the wrong side of history. You see only the loss of old jobs. You're overlooking all the new ones.

The reason they're so easy to overlook is that so much of the new value added is invisible. A growing percent of every consumer dollar goes to people who analyze, manipulate, innovate and create. These people are responsible for research and development, design and engineering. Or for high-level sales, marketing and advertising. They're composers, writers and producers. They're lawyers, journalists, doctors and management consultants. I call this "symbolic analytic" work because most of it has to do with analyzing, manipulating and communicating through numbers, shapes, words, ideas.

Symbolic-analytic work can't be directly touched or held in your hands, as goods that come out of factories can be. In fact, many of these tasks are officially classified as services rather than manufacturing. Yet almost whatever consumers buy these days, they're paying more for these sorts of tasks than for the physical material or its assemblage. On the back of every one of Apple's ( AAPL - news - people ) iPods is the notice "Designed by Apple in California, Assembled in China." You can bet iPod's design garners a bigger share of the iPod's purchase price than its assembly.

Symbolic analysts have been hit by the current downturn, just as everyone else has. But over the long term, symbolic analysts will do just fine--as long as they stay away from job functions that are becoming routinized. They will continue to benefit from economic change. Computer technology gives them more tools for thinking, creating and communicating. The global market gives them more potential customers for their insights. To be sure, symbolic analysts are popping up all over the world. More than half of all Fortune 500 companies say they're outsourcing some software development or expanding their own development centers outside the U.S. But apart from recessions, demand for symbolic analysts in the U.S. will continue to grow faster than the supply.

The nations with the highest percentages of their working populations doing symbolic-analytic tasks will have the highest standard of living and be the most competitive internationally. America's biggest challenge is to educate more of our people sufficiently to excel at them. We do remarkably well with the children from relatively affluent families. Our universities are the envy of the world. Entire regions specialize in one or another kind of symbolic analytic work--Los Angeles for music and film, Silicon Valley for software and the Internet, greater Boston for bio-medical engineering, and New York, until recently, for finance. But we're in danger of losing ground because too many of our kids, especially those from lower-middle class and poor families, can't get the education they need. They're getting low-paid jobs in the local service economy--in retail stores, restaurant outlets, hotels and hospitals.

Some argue that even if I'm correct about all this, the erosion of traditional manufacturing impedes the capacity of Americans to learn these symbolic-analytic tasks, because such learning depends on an intimate understanding of the assembly process. This may be true for a few of these tasks: Manufacturing engineers surely need to know manufacturing inside out, and some design engineers need that knowledge as well. But most symbolic analysts do not. Whatever they need to learn about manufacturing assembly can usually be discovered on line.

Others argue we need more manufacturing assembly operations in the U.S. because our national security depends on it. That seems doubtful. U.S. military contractors subcontract all over the world. As long as they diversify their sources so as not to be dependent on one location or country, we're safe. In the unlikely event that much of the rest of the world where manufacturing is now done suddenly turns on us, we can create the factories and equipment we need. We've mobilized for war before, quite successfully.

It's always possible that the U.S. dollar eventually drops so low that global companies find it cheaper to locate more of their assembly operations in the U.S.--but don't hold your breath. If and when that happens, American consumers will become far poorer than we are today because everything we buy from the rest of the world will be that much costlier.

I don't want to sound like one of those rabid free-market fundamentalists who believes the market always knows best. The market is fallible, as we've recently and painfully experienced. And sometimes we need to consider what's good for our economy and society as a whole regardless of where the market may lead us. But that's exactly where I depart from those who believe we need a larger manufacturing sector in America. Creating and sustaining it would be very costly to American consumers and taxpayers. I just don't get how those costs could possibly be justified.

Read on for more about jobs, manufacturing and the economy in our special report, "Made In America."

Manufacturing Jobs Are Never Coming Back - Forbes.com (16 June 2009)

http://www.forbes.com/2009/05/28/robert-reich-manufacturing-business-economy.html

No comments:

Post a Comment